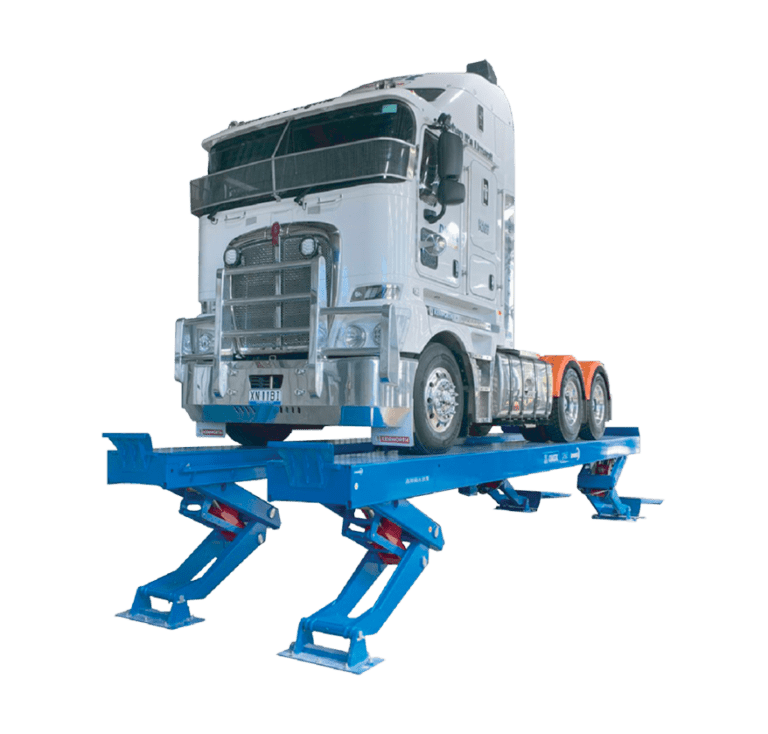

Heavy vehicle tyre changing machines

Workshop tyre changers for truck, bus, mining and agriculture industries

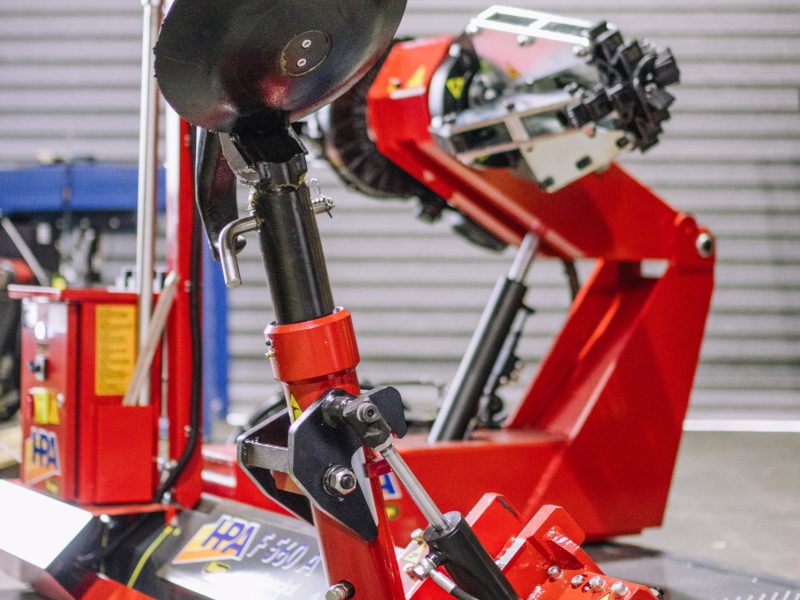

Built in Italy, Levanta’s high quality and durable tyre changers are an excellent investment for every mechanical workshop. One of the key pieces of equipment, we supply one of the most trusted brands to ensure your workshop keeps working.

Talk to our experts

Please use the short form below to get in touch with Levanta about your project, equipment, or servicing needs.

Talk to our New Zealand experts

Please use the short form below to get in touch with Levanta about your project, equipment, or servicing needs.

Levanta: Your Premier Destination for World-Class Tyre Changer Machines

Levanta’s extensive range of tyre changer machines is engineered to meet the unique needs of workshops handling heavy vehicles, ensuring efficient, seamless operation and exceptional results every time.

Workshops catering to heavy vehicles need equipment that can withstand rigorous and the demanding tasks of the industry. Our machines are built to last, delivering consistent performance even under the most challenging conditions. With Levanta, you can trust that your tyre changer machine will be a reliable, efficient and safe investment for your workshop.

We never compromise on quality. Levanta’s commitment to excellence is evident in every aspect of our products. From superior craftsmanship to cutting-edge technology, our tyre changer machines are engineered to deliver exceptional performance and precise operation. Each machine undergoes rigorous testing to ensure it meets the highest industry standards, giving you peace of mind and confidence in your investment.

Quality and Durability

Durability is key in workshops that are constantly servicing heavy vehicles. Levanta understands this need and has designed our tyre changer machines to withstand heavy usage and demanding work environments. With robust construction and high-quality materials, our machines are built to endure and provide years of reliable service, reducing downtime and maximising productivity in your workshop.

Levanta's Comprehensive Tyre Changer Range

As a leader in the industry, Levanta offers a comprehensive range of tyre changer machines. From a standard truck tyre changing machine, 60-inch tractor tyre changing machine, or a truck/ute mounted machine for mobile servicing - our range ensures you can find the perfect tyre changer machine to meet your workshop's specific requirements.

Australia's Trusted Tyre Changer Machines Supplier

Levanta is proud to be a trusted supplier of tyre changer machines in Australia. Our commitment to customer satisfaction and our dedication to providing the best equipment has made us the preferred choice for workshops nationwide. When you choose Levanta, you're choosing excellence, reliability, and unrivalled expertise in tyre changing machines.

Experience World-Class Quality

Discover the difference Levanta's world-class tyre changer machines can make in your workshop. Browse our range today and experience the pinnacle of performance, quality, and durability. Elevate your tyre changing operations with Levanta – your trusted partner for all your heavy vehicle servicing needs.

Frequently Asked Questions

Selecting the ideal tyre changer machine for your needs requires careful consideration of various factors.

- Identify Your Requirements: Begin by assessing your workshop’s specific requirements. Consider the types of vehicles you service, the average tyre sizes you work with, and the volume of tyre changes you handle.

- Consider Compatibility: Ensure that the tyre changer machine you choose is compatible with the tyre sizes and types you commonly encounter. Check the range of rim sizes the machine can handle and verify its suitability for tubeless or tube-type tyres.

- Evaluate Features and Functionality: Pay attention to the features and functionalities of the tyre changer machine.

- Assess Quality and Durability: A sturdy and durable tyre machine can withstand the rigours of daily use, ensuring long-term reliability and minimising the need for frequent repairs or replacements.

- Prioritise Safety: Safety should be a top consideration. Check for safety features such as dual seal check valves to prevent sudden drops in case of hydraulic failure, pressure relief valves to maintain optimal hydraulic circuit pressure, and overload cut-outs to protect against motor overheating.

- Research and Compare Brands: Research different brands and their industry reputations. Look for brands known for their quality, reliability, and customer support. Read customer reviews and seek recommendations to gain insights into the experiences of other users.

- Assess After-Sales Support: Consider the availability of spare parts and the level of after-sales support provided by the manufacturer or supplier. Ensure that you can easy access to technical support and assistance whenever needed.

- Assess After-Sales Support: Consider the availability of spare parts and the level of after-sales support provided by the manufacturer or supplier. Ensure that you can easy access to technical support and assistance whenever needed.

- Set a Budget: Establish a budget based on your workshop’s requirements and financial capabilities. While it’s essential to consider cost, prioritise value for money rather than solely focusing on the lowest price.

Increased Efficiency

With automated features and intuitive controls, Levanta tyre changers reduce the time and effort required, increasing productivity.

Versatility and Adaptability

Tyre changer machines are designed to handle various tyre sizes, types, and configurations, allowing you to work on a wide range of vehicles.

Precision and Accuracy

Tyre changer machines ensure precise and accurate tyre mounting and demounting, minimising the risk of damage to the tyre or rim.

Safety and Operator Well-being

With safety features such as dual seal check valves, pressure relief valves, and overload cut-outs, Levanta tyre changers are designed to create a safer working environment and reduce the risk of accidents or injuries.

Customer Satisfaction

Make quick, efficient, and high-quality tyre changing services a part of enhancing your customers’ satisfaction.

Longevity and Durability

Levanta tyre changer machines are built to withstand the demands of daily use in a workshop environment, reducing the need for frequent repairs or replacements.

Using a tyre changer machine requires strict adherence to safety guidelines to ensure the well-being of operators and prevent accidents. Here are essential safety guidelines and best practices to follow when operating a tyre changer machine:

- Read the Manual: Familiarise yourself with the manufacturer’s instructions and user manual for the specific tyre changer machine you are using.

- Wear Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment.

- Ensure a Safe Work Environment: Before starting any tyre changing operation, ensure the work area is clean, well-lit, and free from obstacles.

- Position the Machine Correctly: Place the tyre changer machine on a stable and level surface. Ensure it is securely anchored to prevent any movement during operation.

- Verify Wheel Compatibility: Check that the wheel you are working on is compatible with the machine’s specifications and capacity.

- Inspect Tools and Components: Regularly inspect the tyre changer machine for any signs of damage or wear. Replace any worn or damaged parts immediately to maintain safe operation.

- Securely Mount the Wheel: Properly secure the wheel onto the machine’s chuck or clamps, following the manufacturer’s instructions. Ensure the wheel is centred and securely held to prevent slippage during tyre changing.

- Use Bead Clamps and Protective Aids: When mounting or demounting tyres, use bead clamps and protective aids to hold the tyre in place and minimise the risk of injury.

- Maintain a Safe Distance: During tyre changing operations, maintain a safe distance from moving parts such as rotating wheels or arms. Avoid placing your hands or body in areas where they may be caught or pinched.

- Operate Controls Carefully: Handle the machine’s controls with caution and operate them smoothly and deliberately. Avoid sudden or jerky movements that could lead to accidents or damage to the tyre or rim.

- Regular Maintenance and Inspection: Conduct routine maintenance and inspection of the tyre changer machine to identify any issues or potential safety hazards.

Levanta’s national network of warehouses and offices means you get personalised after-sales support services geared to offer unmatched customer satisfaction, including support for all tyre changing machines – with offices in QLD, NSW, VIC, SA, and WA.

Scheduled Maintenance Programs

Levanta offers scheduled maintenance programs to optimise tyre changer machine performance, reliability, and longevity. Our experienced technicians conduct routine inspections, perform preventive maintenance tasks, and address potential issues before they escalate, ensuring your tyre changer machines operate at their best.

Request Routine Scheduled Servicing

Technical Assistance

Levanta’s expert technical team provides prompt and knowledgeable assistance to address any queries, concerns, or technical issues you may encounter with your tyre changer machines.

Extensive Spare Parts Availability

We maintain an extensive inventory of genuine spare parts if you require replacement parts for tyre changer machines.

On-Site Service and Repairs

If there are more complex issues or major repairs related to your tyre changers, our technicians can visit your workshop to diagnose and rectify the problem efficiently, minimising downtime.

Warranty Coverage for Levanta Tyre Changer Machines

Levanta provides generous warranty coverage for its range of tyre changing machines. Our warranty includes comprehensive coverage of 5 years warranty on the structure, 2 years warranty on components, and 1 year on tooling and labour. Backed by the best steel fabrication technology, our tyre changers are engineered for durability, longevity, and world-class quality.

Upfront Investment

Levanta provides competitive pricing options for our range of tyre changer machines, ensuring you receive the best value for your investment without compromising quality or safety.

Return on Investment

All of Levanta’s heavy vehicle workshop equipment, including our tyre changer machines, is geared to provide the best ROI.

Yes, Levanta offers delivery of tyre changer machines Australia-wide. With our national network of warehouses, we can supply our workshop equipment directly to your location, no matter where your business is located across Australia. Additionally, we have headquarters, service, and customer service representatives in New Zealand, allowing us to serve customers in both countries. Whether you are in Australia or New Zealand, Levanta is committed to providing efficient delivery and support for your tyre changer machine needs.

Pair of Bead Clamps: Bead clamps are essential for securely holding the tyre’s beads in place during tyre mounting and demounting.

Roller for Tubeless Tyres: Tubeless tyres require special attention during the tyre changing process. This feature helps prevent damage to the tyre sidewalls and ensures smooth and efficient tyre changes.

Set of 4 Jaws: A tyre changer machine equipped with a set of 4 jaws more secure provides a secure and gentle grip, especially for alloy rimmed tyres..

Bead Guide Lever: A bead guide lever assists in guiding the bead over the rim’s edge, making the process smoother and reducing the risk of bead damage.

Clamp for Alloy Rims: To prevent damage to delicate alloy rims, a clamp specifically designed for alloy rims is crucial.

Self-Centering Chuck Activated by a Hydraulic Cylinder: The self-centering chuck ensures a strong and reliable grip on the rim, reducing the risk of slippage or misalignment.

Dual Seal Check Valve: Dual seal check valves prevent the spindle holder from dropping suddenly during a hydraulic circuit failure.

You might be also interested in…

What our customers have to say

Get in touch with us today

Our expert team will be happy to answer any question you have, or provide you with an estimate