Heavy Duty Truck and Bus Knuckle Lifts

At Levanta we pride ourselves on being Australia’s leading supplier of premium Heavy Vehicle Truck and Bus Knuckle Lifts, enabling heavy vehicle workshops to become more efficient, reliable, profitable and safe.

Engineered to take whatever your busy commercial workshop can throw at them, whether you need to lift large vehicles like B-doubles or articulated buses, a heavy vehicle knuckle lift is the ideal choice.

Use independently up to 35t or synchronise up to two or three knuckle lift units to lift up to 105t, Heavy Vehicle Knuckle Lifts provide you with the flexibility you need to take on any job, regardless of vehicle size.

Talk to our experts

Please use the short form below to get in touch with Levanta about your project, equipment, or servicing needs.

Talk to our New Zealand experts

Please use the short form below to get in touch with Levanta about your project, equipment, or servicing needs.

Why Levanta Heavy Duty Truck and Bus Knuckle Lifts are the preferred choice for professionals

Extensive Experience

With years of experience in the industry, Levanta understands the specific needs of workshops and service centres, ensuring our lifts meet the highest standards

Quality and Durability

Our mobile column lifts are built to last, using premium materials and components. They undergo rigorous testing to ensure reliable and long-lasting performance.

Innovative Features

Levanta continuously invests in research and development to bring innovative features to our mobile column lifts, enhancing their functionality and ease of use.

Exceptional Customer Service

We pride ourselves on providing excellent customer service. Our knowledgeable team is always ready to assist you with queries or support.

Competitive Pricing

Levanta offers competitive pricing without compromising quality, providing great value for your investment.

Types of Heavy Duty Truck and Bus Knuckle Lifts

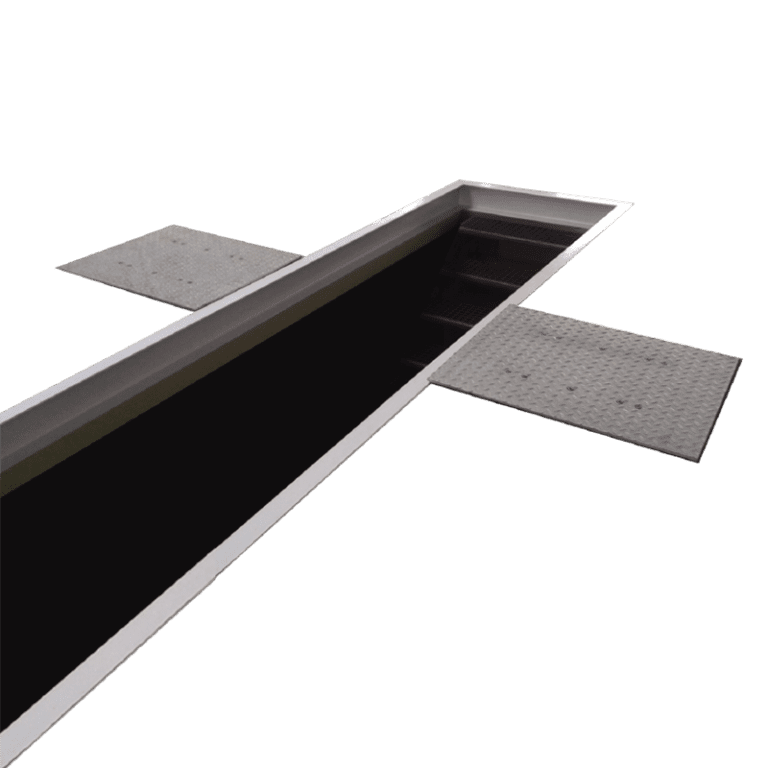

With an impressive lifting capacity of 20 tonnes, the OMER KAR200 stands as a robust heavy-duty knuckle lift engineered for servicing trucks, buses, and other high-capacity vehicles. This model is thoughtfully designed, available in both surface and flush mount configurations, providing versatility in installation.

The KAR200 boasts an innovative electro-hydraulic pantograph lift design, featuring vertical raising that ensures an unobstructed floor space. This unique characteristic makes it particularly well-suited for heavy vehicle maintenance and lifting, eliminating any concerns about floor interference.

Elevate your maintenance operations with unparalleled ease as you experience the seamlessness of lifting and the precision of controlled positioning of the KAR200 Knuckle Lift.

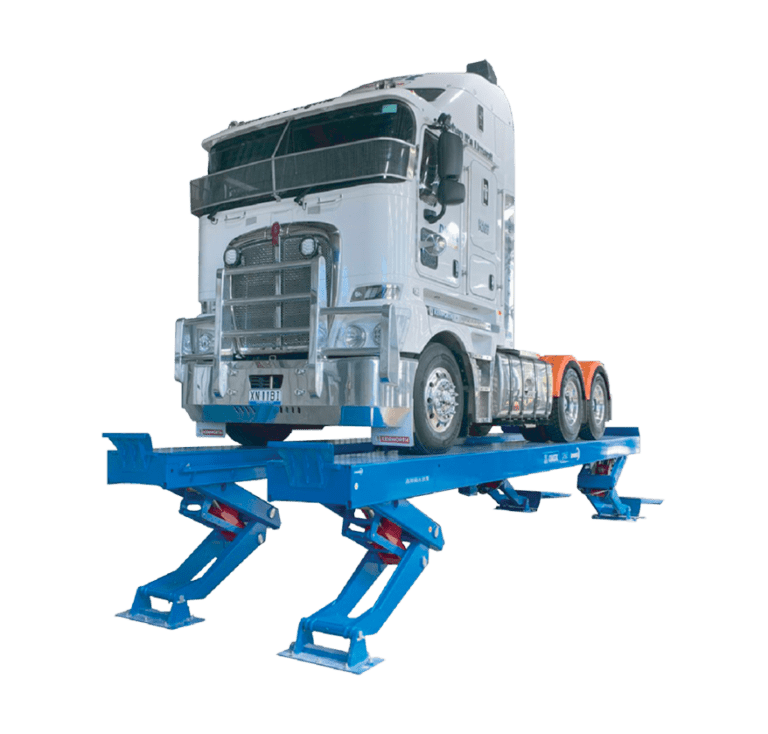

Introducing the OMER KAR250 Truck Knuckle Lift – With a remarkable lift capacity of 25 tonnes, this heavy-duty knuckle lift excels in handling substantial loads. Tailored for larger lifting tasks, it is perfectly suited for lifting lorries, trucks, buses, and other high-capacity vehicles. This model is available in both surface and flush mount options, allowing for versatile installation.

Levanta proudly presents this exceptional knuckle lift, engineered to streamline your heavy vehicle workshop maintenance processes, ensuring safety and unwavering reliability during inspections and repairs.

The KAR250 knuckle lift showcases an innovative electro-hydraulic pantograph design, providing vertical raising that leaves the floor unobstructed. This feature makes it an ideal choice for heavy vehicle maintenance and lifting, eliminating interference concerns.

The KAR250 truck and bus knuckle lift stands as the popular choice for heavy-duty truck and bus maintenance and service workshops, embodying efficiency, power, and reliability.

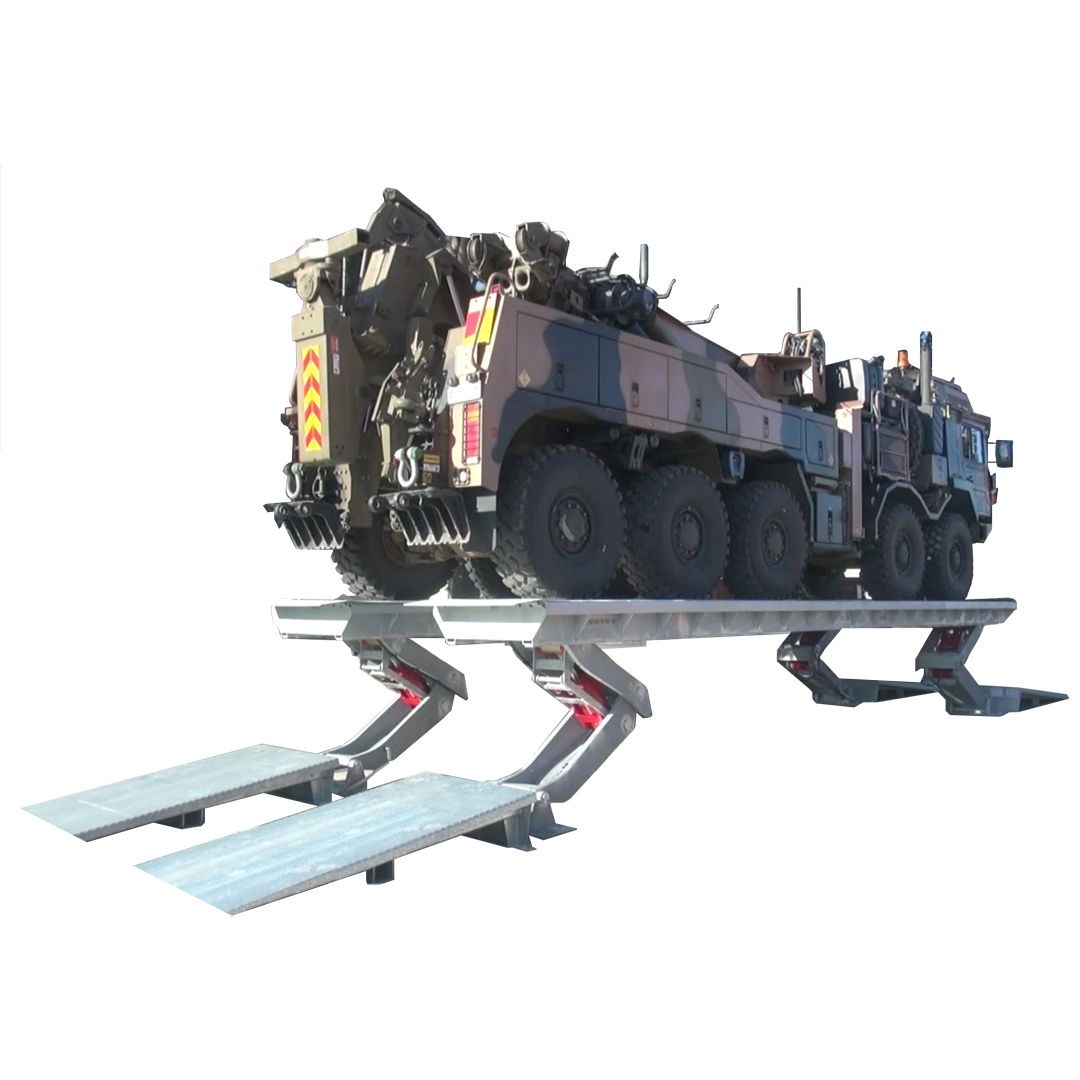

With a capacity to lift up to 35t, this heavy duty knuckle lift is ideally suited for the bigger side of lifting. Discover the dynamic fusion of power and precision with the OMER KAR350 Truck Knuckle Lift, exclusively available at Levanta. This remarkable knuckle lift is engineered to lift heavy trucks, lorries, buses and any other large capacity vehicle with unparalleled control and accuracy.

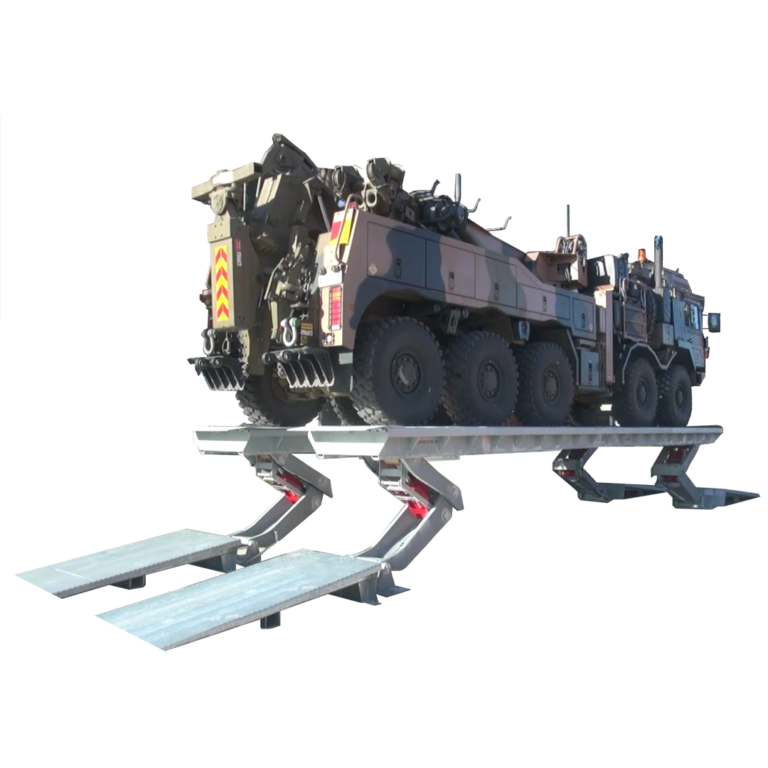

With an remarkable lifting capacity of 54 tonnes, OMER KAR540 is Levanta’s heaviest lifting knuckle lift engineered for servicing the heaviest vehicles including military vehicles, mining equipment, agricultural equipment, emergency service vehicles, large trucks, buses, and other super heavy duty vehicles.

Levanta offers the option to synchronize all knuckle lifts into a twin version. This ingenious option allows you to cater to longer vehicles, trailers, prime movers, semi-trailers, and more. By pairing two knuckle lifts, you effectively double your lifting capacity, and eliminating downtime associated with disconnecting trailers for servicing.

Frequently Asked Questions

Levanta heavy vehicle knuckle lifts are suitable for a wide array of industries and vehicle types, encompassing a broad spectrum of applications. While there are no restrictions on the use of these lifts, they are most frequently employed in the following scenarios: heavy-duty trucks, B-Double, A-Double, B-Triple, AB-Triple, A-Triple, BAB-Quad, ABB-Quad, Rigid Truck, and Dog Trailers, along with semi-trucks/semi-trailers, buses, military vehicles, and more.

The Levanta Truck & Bus Knuckle Lifts incorporate a comprehensive range of safety features, ensuring a secure and reliable lifting experience:

Control Console with Dead Man’s Buttons: The control console is equipped with dead man’s buttons, designed for simplicity and user-friendliness. This dead man control enhances operator safety by requiring continuous engagement.

Mechanical Safety Locks: The lift is fortified with mechanical safety locks that effectively secure the lifting process, preventing unintended movement during operation, bolstering overall safety.

Piston Air for Safety Lock Activation: The mechanical safety locks are activated using piston air, contributing to their dependable and controlled engagement. This system ensures consistent and reliable safety mechanisms.

Burst Valve and Pressure Relief Valves: Each lifting piston is outfitted with a burst valve, situated at the rear, and accompanied by hydraulic hoses designed to handle high pressures. Additionally, the lifts are equipped with five distinct pressure relief valves, further enhancing safety measures.

Acoustic Warning and Bypass Key: An acoustic warning system is incorporated, triggering when the lift is positioned just 500 mm away from the collapsed position.

Anti-Slip Platform Finish: To prevent slippage and enhance traction, all platform surfaces feature an embossed anti-slip finish. This design choice ensures stability for both operators and the lifted vehicles.

Electronic Balance System with Automatic Leveling: The lifts are equipped with an electronic balance system that facilitates automatic leveling. This feature ensures that the lifted load remains stable and secure throughout the lifting process.

Runway Leveling Control with Photo Sensors: The inclusion of photo sensors allows for precise control over the leveling of the runways. These sensors enable accurate adjustment, contributing to a consistent and safe lifting experience.

Through the integration of these safety features, Levanta Truck & Bus Knuckle Lifts offer a reliable and secure lifting solution that prioritizes the well-being of operators and the protection of lifted vehicles.

Warranty Coverage

Levanta provides generous warranty coverage for its range of Bus & Truck Knuckle Lifts. Our warranty includes comprehensive coverage of 5 years warranty on the structure, 2 years warranty on components, and 1 year on tooling and labour. Backed by the best steel fabrication technology, our vehicle hoists are engineered for durability, longevity, and world-class quality.

Installation and Space Requirements for Heavy Vehicle Knuckle Lifts

Levanta’s expertise as a specialist in heavy vehicle workshop fit-outs extends to providing comprehensive installation support and guidance:

Seamless Installation Services: Leveraging the expertise of Levanta’s technicians, the installation process is conducted to highest standards, to guarantee a secure and accurate approach to vehicle lifting.

Best Return on Investment

Levanta’s suite of heavy vehicle workshop equipment yield best return on investment. This investment translates to heightened efficiency, minimised downtime, and heightened productivity within your workshop operations, resulting in long-term cost savings.

Scheduled Maintenance Programs

Levanta offers scheduled maintenance programs to optimise truck and bus knuckle lifts performance, reliability, and longevity. Our experienced technicians conduct routine inspections, perform preventive maintenance tasks, and address potential issues before they escalate, ensuring your truck and bus knuckle lifts operate at their best.

Request Routine Scheduled Servicing

Technical Assistance

Levanta’s expert technical team provides prompt and knowledgeable assistance to address any queries, concerns, or technical issues you may encounter with your truck and bus knuckle lifts. Whether you need guidance on maintenance procedures, troubleshooting support, or clarification on operating truck and bus knuckle lifts, our team is dedicated to providing comprehensive technical assistance.

Extensive Spare Parts Availability

Levanta understands the importance of minimising downtime in your workshop, including your heavy lifts. Our efficient spare parts supply chain ensures you can quickly access the necessary components to keep your heavy lifts operational and minimise disruptions to your workshop operations.

On-Site Service and Repairs

If there are more complex issues or major repairs related to your truck and bus knuckle lifts, our technicians can visit your workshop to diagnose and rectify the problem efficiently, minimising downtime.

Training and Operator Certification

Levanta provides comprehensive training programs for workshop equipment operators and technicians, including training on truck and bus knuckle lift safety, maintenance and efficiency.

Discover the exceptional features of Levanta’s Truck & Bus Knuckle Lifts:

- Robust Lifting Strength: The lifting capacity of these knuckle lifts is evident through specially engineered solutions for this model. Tubular structure runways and resilient metal sheeting are adept at enduring demanding conditions, including asymmetric loads.

- Vertical Leg Design: The lift’s innovative leg design support heavy-duty vertical movement. This design not only facilitates vertical force distribution to the foundation but also incorporates an electronic balancing system with automatic leveling for unparalleled stability.

- Innovative Piston Housing: The piston is ingeniously housed at the upper part of the leg, offering protection against debris falling from vehicles and potential damage from inadvertently dropped tools.

- Electronics-Free Efficiency: The “torsion bar” master-slave synchronism, nestled within the control box, ensures easy maintenance and minimal downtime. The mechanical/hydraulic system eliminates electronics, enhancing reliability.

- Resilient Torque & Deformation Resistance: Structural stress is minimised, amplifying the unit’s lifespan. The box structure’s enhanced resistance to flexion and torque withstands heavier loads without compromise.

- Enhanced Workspace: Technicians enjoy a more comfortable and accessible vehicle maintenance environment, thanks to the open space design.

- Stability Without Sliding Points: Four fixed points devoid of sliding elements instill superior stability and reduced resistance to torque or deformations. Additionally, cantilever points are non-existent on the platforms.

- Safety Beyond Compare: The knuckle lift range prioritises safety with an array of features:

– Control console integrates dead man’s buttons for intuitive operation.

– Mechanical safety locks secure the lift during operation, with compressed air employed to activate them.

– Burst valves positioned at the rear of each lifting piston, reinforced with high-pressure hydraulic hoses, and supported by five distinct pressure relief valves.

You might be also interested in…

What our customers have to say

Get in touch with us today

Our expert team will be happy to answer any question you have, or provide you with an estimate