Inland Petroleum, a family-owned fuel distributor serving New South Wales, has proudly operated for three generations. Established in 1985, the company has grown to become a trusted partner in fuel distribution.

As their fleet grew, it became clear that relying on multiple external service providers was no longer cost-effective or efficient. The high labour rates and inefficiency of external servicing became unsustainable. To meet the operational demands of a larger fleet, Inland turned to Levanta to help establish an in-house maintenance workshop equipped with advanced tools for efficient, high-quality servicing of heavy vehicles.

The Challenge

With a rapidly growing fleet, Inland Petroleum faced challenges in maintaining efficiency, reducing costs, and minimising downtime. Managing maintenance externally was costly and didn’t allow Inland the control or speed required to keep up with fleet demands. Inland needed high-quality, durable equipment that could simplify the maintenance of large, multi-axle vehicles, enabling them to conduct preventive maintenance and quickly diagnose and repair issues.

Levanta's Solution

Levanta provided Inland Petroleum with a range of advanced equipment designed for heavy vehicle servicing, including:

- BM20200 Mobile Roller Brake Tester – Facilitates single-operator brake testing for long, multi-axle vehicles.

- BM53000 Mobile Play Detector (Shaker) – Provides accurate diagnostics for wheel bearing and suspension issues.

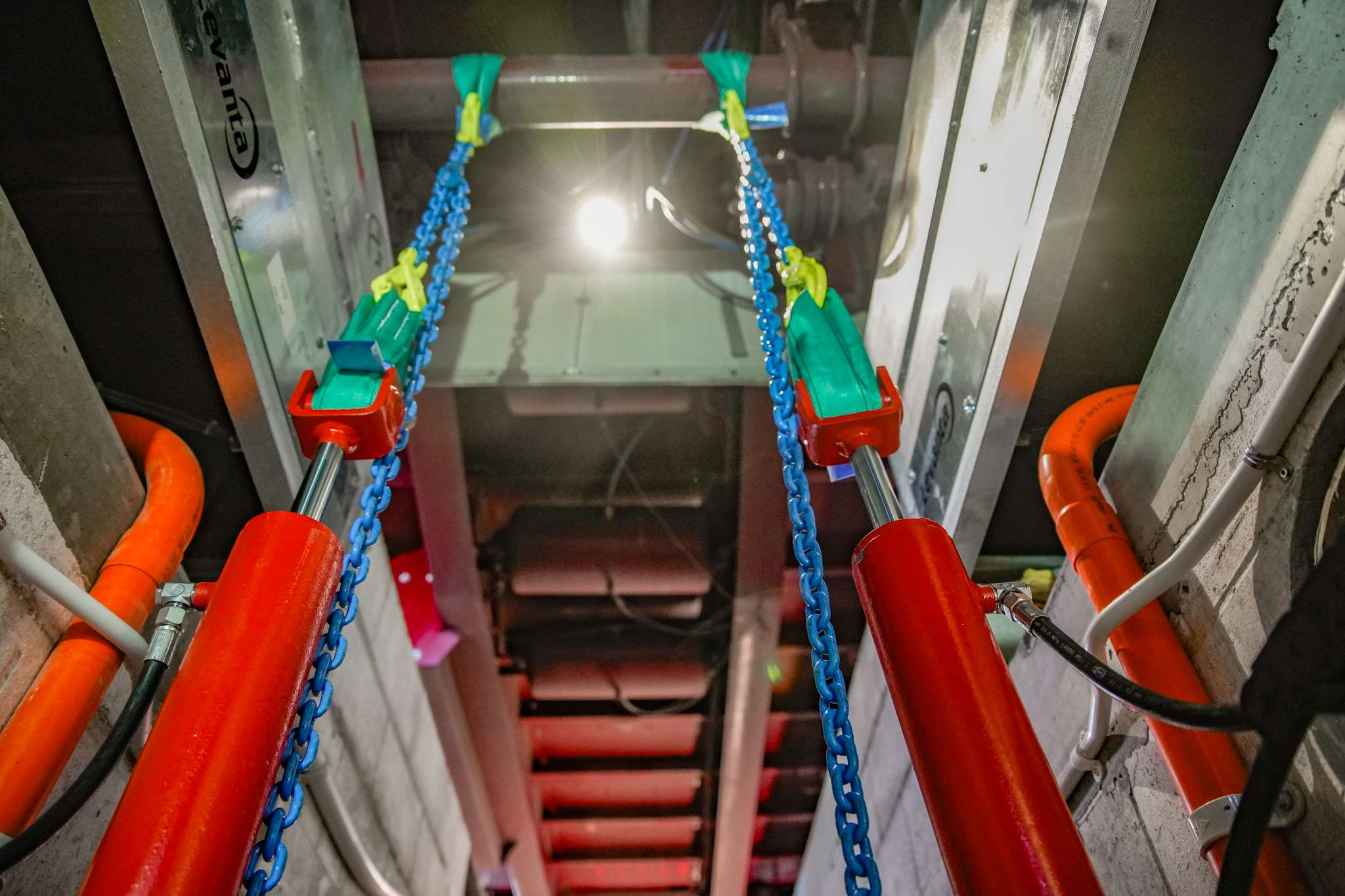

- LiftMax LM65W Wireless Column Lift – Wireless, versatile lifting solution ideal for tankers and trailers.

- OMER KAR250 Twin Truck Knuckle Lift – Heavy-duty lift with flexible load distribution, accommodating up to 38 tons per lift, centrally loaded.

- Josam Cam Aligner – Ensures precise wheel alignment, improving handling, tire wear, and overall fleet safety.

- LiftMax LM80S 8-Ton Axle Stands – Provides stable support when vehicles are elevated on lifts, allowing additional lifts to be freed up for other projects, enhancing workflow efficiency and safety.

Results and Benefits

Since adopting Levanta’s equipment, Inland Petroleum has experienced substantial operational improvements, including a 38% reduction in monthly repair and maintenance costs. Shifting maintenance in-house has also enabled Inland to create new jobs, adding 15 positions within their local community. The implementation of Levanta’s tools has streamlined Inland’s ability to conduct preventive maintenance, resulting in less fleet downtime and increased efficiency.

“After 14 months of using Levanta equipment, we’ve been able to measure a 38% monthly cost reduction in repair and maintenance.

Levanta has helped us achieve less downtime through getting us back to a point of doing preventative maintenance instead of reactive maintenance. Over the last 14 months, we’ve got the equipment, trucks and trailers back to a standard now where it is only preventative maintenance, unless we have a major breakdown.

This means we’ve got more equipment on the road, there’s a lot less downtime and we’re a lot more efficient in what we’re doing as a company.”

Drew McCallum, Director – Inland Petroleum

Inland Petroleum Workshop Feedback

Experience the Levanta Difference

Through their partnership with Levanta, Inland Petroleum has effectively transitioned to in-house maintenance, significantly cutting costs and reducing downtime.

Equipped with Levanta’s advanced heavy vehicle workshop equipment, Inland has established a highly efficient, safety-focused workshop capable of handling the demands of a growing fleet. Inland’s fleet remains reliable and road-ready, with Levanta as a trusted partner supporting every kilometre of their journey.

For those seeking to elevate their workshop capabilities, Levanta offers unmatched expertise and service. To learn more about how Levanta can transform your workshop, contact our team to get started today.

Get in touch with us today

Our expert team will be happy to answer any question you have, or provide you with an estimate