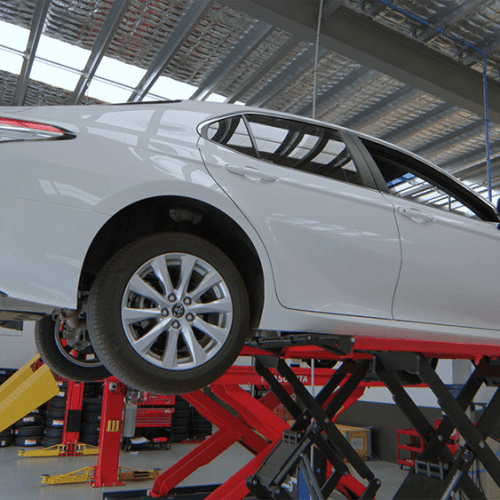

Looking for a safe and reliable maintenance facility for their light to medium plant, The Australian Defence force and John Holland construction engaged Levanta based on our experience and history of the right solution for the job. Brake testers, lubrication, exhaust extraction and compressed air systems were designed, supplied and installed in this defence project.

Project Challenge

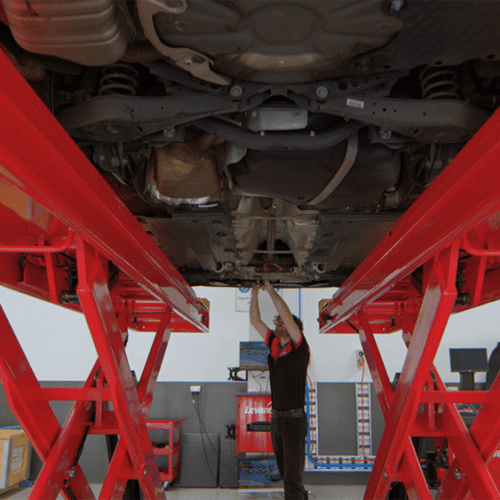

The Client, John Holland Constructions and the Australian Defence Force, were building a new maintenance facility for their light to medium plant. They required a high availability lube reticulation system, exhaust extraction system and compressed air. In addition they also identified the need for a safe and reliable solution for lifting a wide range of vehicles and other equipment, as well as a roller brake tester and tyre changer for medium vehicles.

Our Solution

The project went to tender and Levanta was successful in their bid as a sub-contractor to a Sydney Based company that was doing the HVAC and other engineering systems for the hydrocarbon (oil) reticulation and compressed air work packages. We were also successful in a direct bid for the Lifting, Brake Testing and Tyre Changer package.

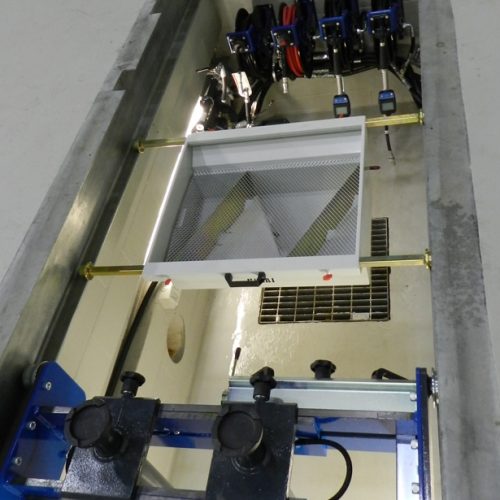

The project included:

- Over 2000 metres of 316 Stainless Steel oil pipework

- Over 500 metres of Aluminium Infinity Air pipework

- 5 Heavy Duty Lube Stations capable of taking 8 reels each and also incorporation Waste Oil and Waste Coolant recovery points on each stand

- 16 x 200mm Diameter exhaust extraction reels with electric extension and retraction

- 3 x new oil, 1 x waste oil and 1 x waste coolant tanks

- BM Mobile Roller Brake Tester

- HPA 56” Truck Tyre Changer

- 26 x LiftMax 7.5t Wireless mobile column lifts with 7.5 ton axle stands

- 3 x high capacity rotary screw air compressors and 2 x smaller mobile piston compressors

Client Benefit

Working as a sub-contractor, we delivered to brief, to budget, on time and as promised. The result was a successful design, supply, manufacture and install of specific components within the full fit out, which allowed Australia’s Defence Force to successfully service and maintain critical vehicles and equipment.

Get in touch with us today

Our expert team will be happy to answer any question you have, or provide you with an estimate