MJ Smith is a company that takes immense pride in the maintenance of their fleet and the reputation of their brand. Their main depot and workshop is a testament to this dedication, remaining spotless and in pristine condition despite daily use and rigorous cleaning routines.

Founded in 2004 as MJ Smith Ground Preparation, the company started with a single bulldozer, performing small local jobs. Today, the MJ Smith Group boasts a fleet of over 65 pieces of plant and equipment and employs 45 staff members, ranging from senior management to labourers.

Their new workshop facility is in the small rural town of Woodenbong, strategically positioned 10 km south of the Queensland border and just five kilometres from the junction of Summerland Way and Mount Lindesay Road, providing easy access to Legume and Tenterfield.

MJ Smith handles numerous civil construction projects and heavy haulage contracts across the region – serving the Northern Rivers of New South Wales and extend their services throughout Southeast Queensland.

Overview of the Project:

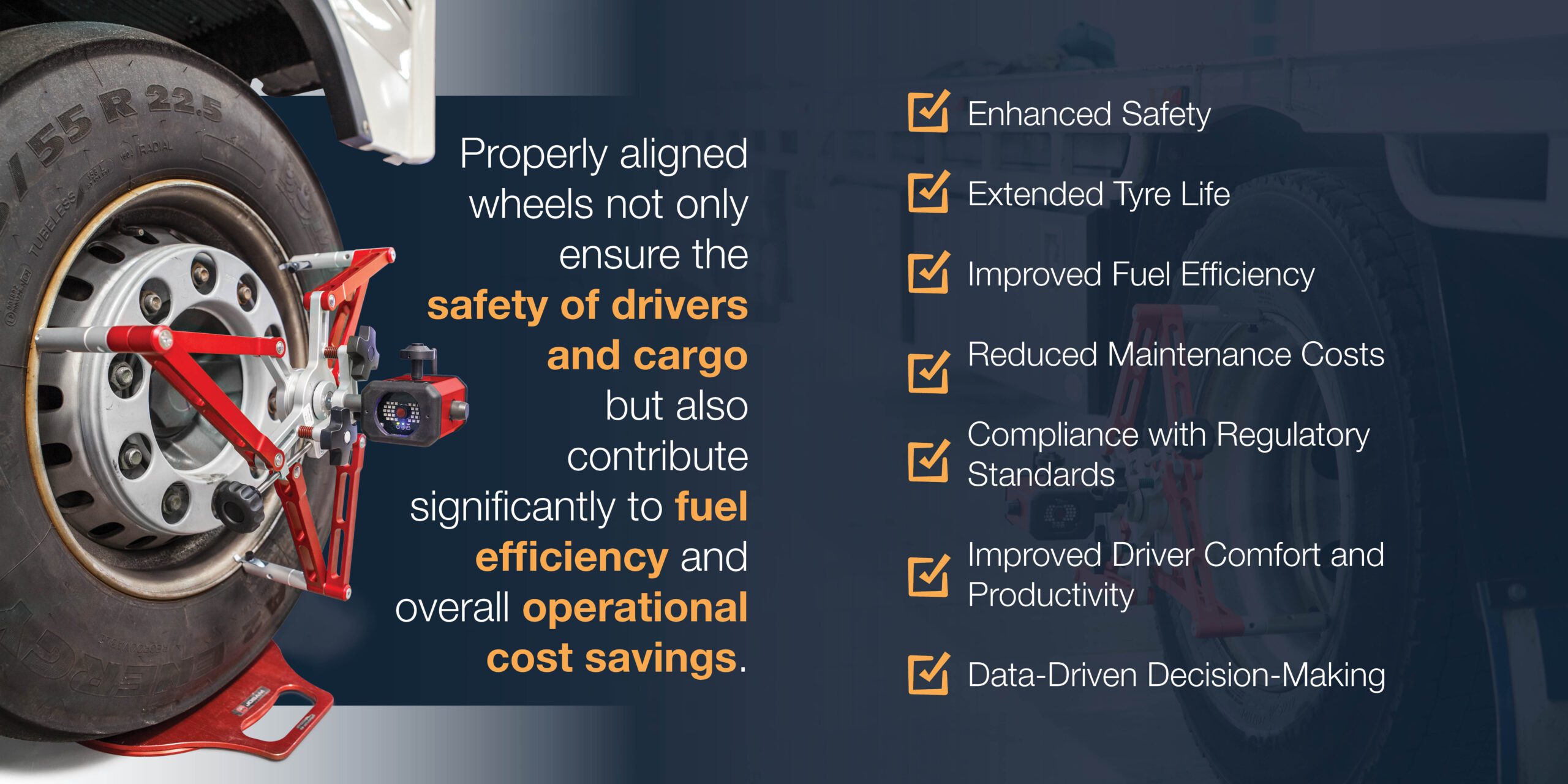

With a fleet of late-model, low-hour equipment and a team of highly experienced operators, MJ Smith guarantees reliability and first-class equipment and results. Their commitment to excellence is evident in their immaculate workshop, which is equipped to perform servicing and preventative maintenance on range of machinery, including prime movers and earthmoving equipment.

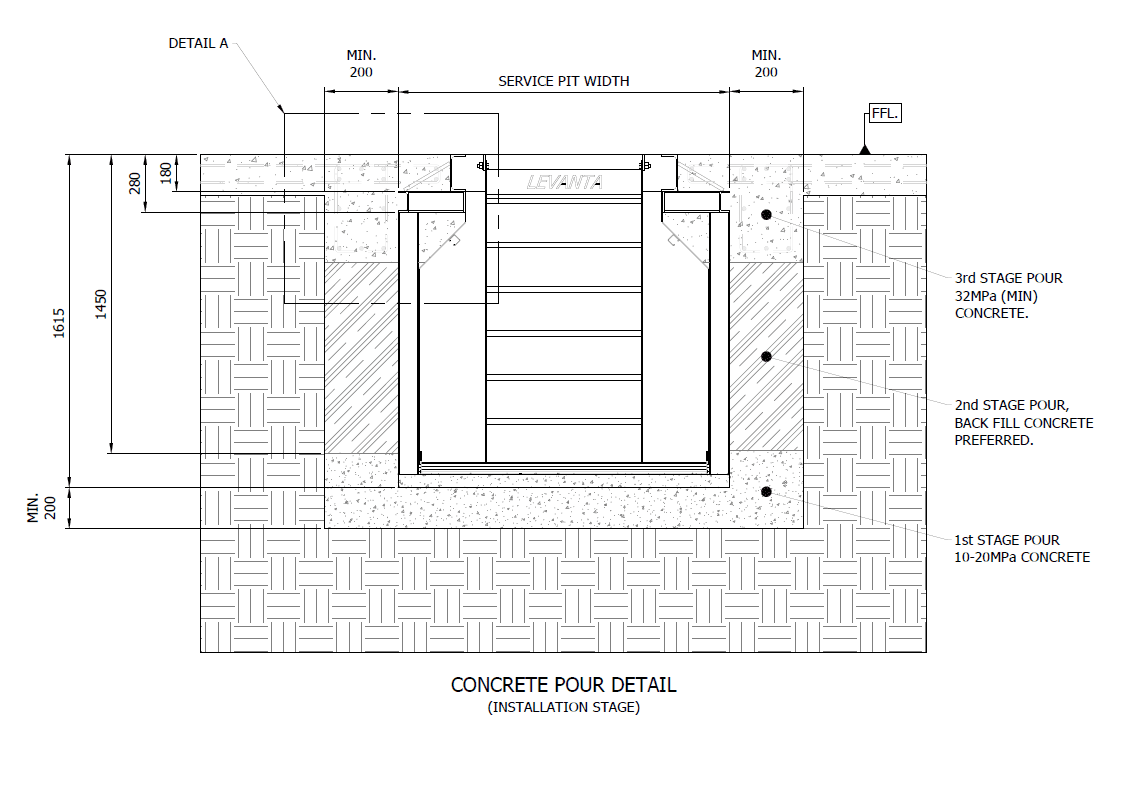

The workshop fitout supplied by Levanta enables MJ Smith’s staff to maintain their equipment at peak performance. This project included a range of Heavy Vehicle Workshop Equipment sourced from our world class European suppliers and an Australian-made Levanta prefabricated service pit – all installed so that MJ Smith’s fleet and assets are operating at peak performance, ensuring that the company continues to deliver top-notch service and uphold their esteemed reputation.

The Project Included

- JFL13 - Jager 13.6T 4 Post Hoist with 8m Platforms

- Heavy Duty Jacking Beam – 6T

- 25m Levanta Prefabricated Service Pit

- Air Hydraulic Twin Ram Pit Jack

- LWS046-1457-000 Waste Drainer Suits Pits 90L

- Oil Gantry and Hose Reels

- Oil Pumps and Delivery System

- VLT12 Hydraulic Transmission Jack

- AS3 – Heavy Duty Gearbox Saddle

- LWS045-1460-000 Upright Waste Drainer & Basin 90L

Why Was Levanta Chosen:

In keeping with their unwavering commitment to excellence, MJ Smith sought out a partner who could match their high standards for their new workshop fitout in Woodenbong. Levanta emerged as the preferred choice, renowned for delivering turnkey solutions characterized by quality equipment, meticulous installation, and exceptional service.

Levanta’s expertise in the manufacturing and installation process made us the perfect partner for this project. Our extensive experience in overseeing the installation of service pits, workshop equipment, reticulated oil and air delivery systems, and a broad array of other essential components ensured that MJ Smith’s workshop would be outfitted to the highest standards.

The seamless integration of all elements provided by Levanta ensured that the workshop was ready for immediate use, allowing MJ Smith to maintain their equipment and uphold their reputation without missing a beat. Our shared commitment to quality and reliability made Levanta the ideal partner for MJ Smith’s ambitious project.

To experience the Levanta difference for your own workshop needs, contact our team to get started today.

Get in touch with us today

Our expert team will be happy to answer any question you have, or provide you with an estimate