Revolutionising Heavy Vehicle Workshops:

PREFABRICATED STEEL PITS VS. TRADITIONAL CONCRETE CONSTRUCTION IN AUSTRALIA AND NEW ZEALAND

In the world of heavy vehicle workshops, choosing the right foundation for your maintenance pits is crucial. Traditionally, concrete pits have been the go-to option, but with the advent of prefabricated steel pits, there’s a compelling case to be made for rethinking this age-old choice. In this article, we’ll explore the benefits of both options and present a compelling argument in favour of prefabricated steel pits for heavy vehicle workshops in Australia and New Zealand.

The Case for Concrete Pits:

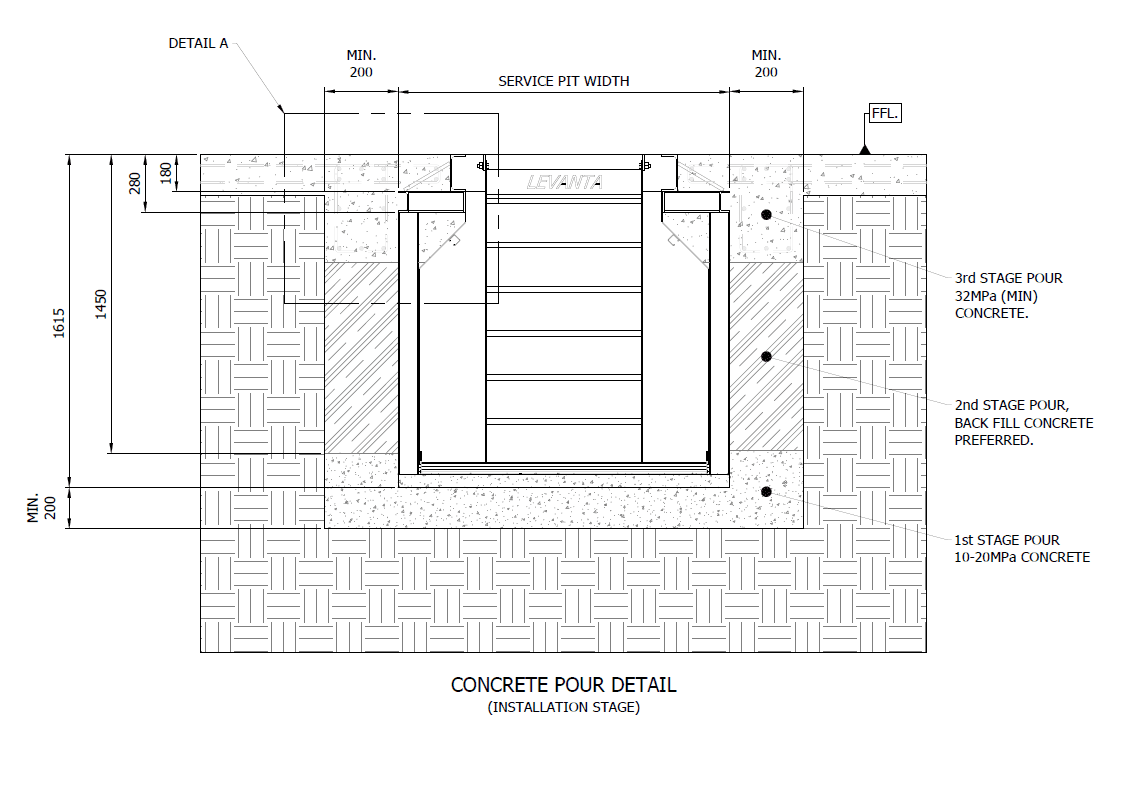

Concrete pits have been the standard choice for decades, and for good reason. They offer durability, strength, and a certain level of customisation. Concrete is a familiar material in the construction industry, making it widely available and cost-effective. Additionally, concrete pits have proven to withstand heavy loads and harsh environmental conditions.

Concrete also provides a solid foundation for heavy-duty machinery, and its density can help reduce noise levels in the workshop. These factors, combined with the familiarity of concrete construction methods, often make it the default choice, especially when financial constraints are a significant consideration.

The Revolution of Prefabricated Steel Pits:

While concrete pits have their merits, prefabricated steel pits bring a host of advantages that can’t be overlooked, even in the face of financial constraints. Here’s why:

Speed of Installation:

Prefabricated steel pits are manufactured off-site and delivered ready for installation. This significantly reduces construction time compared to the labour-intensive process of pouring and curing concrete. A quicker installation means less downtime for your workshop, ensuring you can get back to business sooner.

Cost-Effective in the Long Run:

While the initial cost of prefabricated steel pits may be higher than concrete, the long-term savings are substantial. Steel is highly resistant to corrosion and requires minimal maintenance, which translates to lower repair and replacement costs over the years. Additionally, the faster installation process means less labour costs, contributing to overall savings.

Customisation and Flexibility:

Prefabricated steel pits can be designed and manufactured to meet the specific needs of your workshop. Whether you require additional drainage features, specialised configurations, or integrated systems, steel allows for a higher degree of customisation compared to traditional concrete construction.

Durability in Extreme Conditions:

Prefabricated steel pits are engineered to withstand extreme environmental conditions, including high temperatures, humidity, and corrosive substances commonly found in heavy vehicle workshops. This durability ensures a longer lifespan and reliable performance even in challenging situations.

Structural Integrity and Safety:

The structural integrity of prefabricated steel pits is designed to meet or exceed safety standards. These pits offer a robust and secure foundation, providing a safer working environment for technicians and reducing the risk of accidents or structural failures.

Advanced Technological Features:

Modern prefabricated steel pits can be equipped with advanced technological features, such as integrated inspection lighting, ventilation systems, automated trade waste systems, automated pit covers, heavy vehicle inspection equipment (brake and suspension testing) and much more. These features enhance efficiency, streamline maintenance procedures, and contribute to a technologically advanced workshop.

Reduced Disruption During Installation:

The off-site manufacturing of prefabricated steel pits minimises on-site disruption during installation. The precise engineering and pre-fabrication result in a smoother and quicker installation process, reducing the impact on ongoing workshop operations.

Turnkey Solutions for Time-Efficient Fit-Outs:

Prefabricated steel pits offer a distinctive advantage by arriving fully fitted out, streamlining the entire fit-out process. Unlike traditional concrete pits that often require additional time and effort for fitting out, prefabricated steel pits arrive on-site with essential components and features already in place.

Compliance with Industry Standards:

Prefabricated steel pits are designed and manufactured to comply with industry standards and regulations. Choosing a product that adheres to these standards ensures that your heavy vehicle workshop operates in accordance with safety and quality guidelines.

Minimal Site Preparation Requirements:

Prefabricated steel pits often require less site preparation compared to traditional concrete construction. This can lead to additional cost savings and a more straightforward installation process, especially in situations where site conditions may pose challenges.

Conclusion:

While concrete pits have been a traditional method of service procedures in heavy vehicle workshops, the introduction of prefabricated steel pits presents a new and compelling case for change. The advantages of speed, long-term cost savings, customisation, environmental considerations, and portability make steel a worthy investment, even for businesses mindful of financial constraints.

An extraordinary level of craftsmanship and technology goes into the making of each Levanta prefabricated workshop service & inspection pit, ensuring a safe, comfortable area that will help increase the overall efficiency of your heavy vehicle workshop whilst complying to all relevant Australian and New Zealand industry standards/guidelines.

By choosing Levanta’s Prefabricated Service and Inspection Pits, heavy vehicle workshops in Australia and New Zealand can enjoy the benefits of a modern and efficient foundation that meets both their operational and budgetary needs.

Enquire Today; contact the Levanta Project team!