Which is best for your workshop business?

According to the NTARC (National Truck Accident Research Centre), 25% of all accidents are caused by speed, 12.1% by fire losses and mechanical failure, and 11.9% by fatigue. Importantly, each of these top three causes has contributory brake issues.

With the 2013 release of NTARC’s major accident report which states that brake problems can result in tyre fires and explosions, recommendations are being made that brake and tyre maintenance become a priority.

Coupled with the recent woes of one of Australia’s largest transport companies being issued with multiple defect notices for brake, wheel and suspension faults (taking 26 of their 80 strong fleet off the road), the major impact on company earnings and reputations cannot be ignored. And neither can the cause.

The different types of brake testing equipment

It’s clear to see that brake testing is an important part of your heavy vehicle fleet maintenance. But which type of brake tester will be best for your business? The Levanta team gives you all the information you need below.

As with almost any product, there are multiple types of brake testers available. The three main contenders are decelerometers, plate testers and roller testers.

1) Brake testing with decelerometers

The most common and cost effective piece of brake test equipment is the decelerometer. Usually found strapped to the passenger seat of the vehicle being tested, this equipment measures and records the inertial force of the vehicle as it decelerates from a pre-determined speed to a stop. Service brake speed is generally around 30kmh, with the park or emergency brake speed being 15kmh.

While there are plenty of different types of decelerometer available on the market, they all basically work off the same “g-force” principle. The transducer or pendulum is read to determine if the vehicle can develop enough brake force to theoretically stop the vehicle safely within a set range of distances.

Being relatively inexpensive and fairly compact, the decelerometer allows ease of use in most environments.

You have the option of printed paper tape to provide results, and maintenance is cheap and easy, with annual calibration ensuring the accuracy and legality of your testing. Decelerometers are fitted in the vehicle cabin, so mud and dirt is not an issue.

The disadvantages of decelerometers

Where decelerometers fall down is that they don’t provide information about individual wheel performance. This type of testing will also not show hidden faults like drag and cracked or warped brake drums or disks, as it doesn’t weigh the vehicle.

Motion is also a factor, as the vehicle must be moving for testing to be conducted. so there is potential safety issues due to the possibility of the operator getting distracted.

2) Plate testing of brakes

The second type of brake testing is called plate testing. While similar to a decelerometer in that it measures the inertial deceleration force of a vehicle being driven at a pre-determined speed, the plate tester is installed in a static position on the ground and the vehicle is driven on to it. The brakes are then applied while the wheels being tested are on the skid plates, allowing the reading of sideways movement of the vehicle wheel under braking as well.

Plate testers can be powered with an extra low voltage source (12vdc), which means minimal exposure to low or high voltage AC power. Plate testers also have fewer moving parts, principally the plate itself, and provide a more in-depth test, allowing weighing of vehicle axle (static) than decelerometers.

The disadvantages of plate testers

Like decelerometers, plate testers require the vehicle to be in motion to be tested. This can cause a greater level of distraction, as the operator must concentrate on keeping the vehicle at the correct speed, lining up on the plates, and then applying the brakes at the exact moment they hit the plates.

This is especially important for long vehicle testing such as road trains or B-doubles. Usually this would require other helpers to work with the operator, which can result in reduced consistency in some test situations.

3) Roller brake testers

The final method is roller brake testing, in which vehicles are driven onto a set of rollers which are covered in a plastic medium infused with friction material. During testing the wheels are turned by the constant speed of the roller, keeping the vehicle static during the test.

Roller brake testing measures deceleration by means of torque force produced by the decelerations of the wheel against the rollers. This method produces the most consistent results across all axles. You can test one wheel at a time, review efficiency of service, and test parking and emergency brakes.

Roller brake testers can be configured for air pressure testing, ovality (warped or cracked discs/drums), and bind (rolling resistance). Additionally, some makes allow you to accurately test time lag, which can help reduce the likelihood of “jack-knifing”. Impressively, roller brake testing gives you the ability to match prime movers to trailers, maximising the vehicle’s balance and efficiency.

This style of testing offers greater safety, with the single operator system allowing control on some systems direct from the vehicle cab via remote control. There are also a number of options to enhance the system including speedo checking, play detectors, emission testers, headlight aimers and noise meters. With these accessories, the unit has the added advantage of forming the basis of a complete vehicle test lane.

The disadvantages of roller brake testing

While the roller brake tester sounds like the darling of the three methods, it’s not without its downsides. Due to the powerful drive systems, they generally require 3 phase power to operate and can be dangerous to operators if safety precautions are not strictly adhered to.

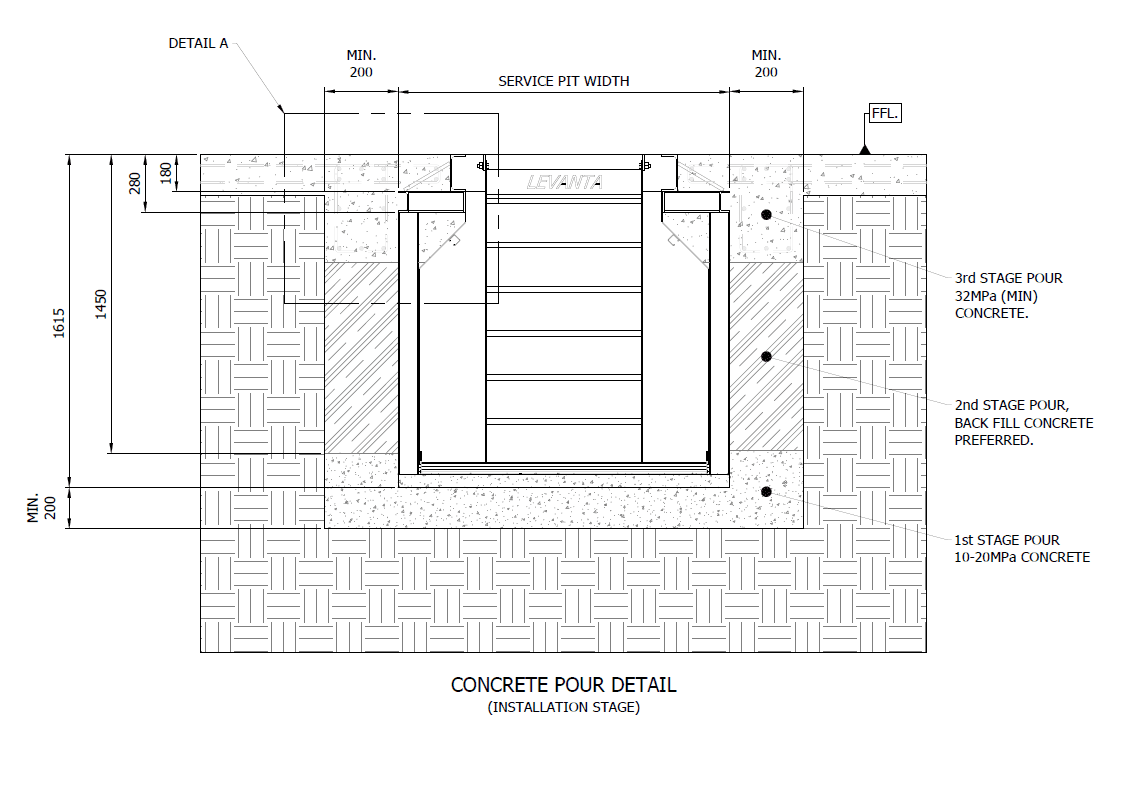

The weight of the mobile units can be prohibitive (weighing in a 1.2t for the brake tester). Installation can also present some challenges, with the in-ground units requiring some civil work to get the job done.

Choosing the right brake tester for your needs

Operation

Roller brake testers will measure the torque reaction generated by the vehicle brakes against a roller turned by a motor, while the plate brake testers have strain gauges attached to a plate supported on bearings, and measure the forces required to hold the plate, when a vehicle is braked on top of it. Decelerometers are placed in the vehicle and have a pendulum (more recently, airbag type accelerators) that moves when a vehicle is braked. The amount of ‘swing’ on the pendulum is measured to indicate deceleration during braking.

Safety

Roller brake testing is a comparatively safe method of testing, as the vehicle does not move during the brake test. Instead the rollers act as the road and turn under the wheels. With both the plate brake tester and the decelerometer, testing requires the vehicle to be driven and braked on the plates, usually within the confined space of a vehicle workshop or roadside. This could be a hazard to other road or workshop users.

Accuracy

Roller brake testers use the same braking surfaces to test all of the wheels, on all of the vehicles; ensuring accurate comparative tests. Plate brake testers use the same braking surfaces for all of the wheels, on all of the vehicles, while the decelerometer tests on-road so the braking surface can vary from very good to very bad, depending on conditions.

While roller brake testers test all vehicles at a consistent test speed, both the Decelerometer and Plate Brake Testers tend to test at variable test speeds; depending on how the vehicle is driven.

Adaptability

Roller brake testers can test the entire range of every brake fitted to the vehicle, from zero to full braking, or wheel lock, consistently and repeatedly, without the influence of momentum or weight transfer. The plate brake testers and decelerometers cannot test the entire range of a vehicles brake successfully.

Decelerometers cannot test individual axles, plate brake testers can compare the balance of brakes across individual axles, while roller brake testers are able to consistently and repeatedly compare the balance of the brakes across individual axles.

Here are some other resources on Brake Testers that you might find interesting:

Case study: Cleanaway Dandenong fitout including brake tester

How to set up your roller brake tester for best results

Should you carry out static or dynamic roller brake testing?

Heavy vehicle brake testing criteria update

Power

Roller brake testers use external power for the brakes to work against, typically electric motors, therefore the time taken for the test can be controlled by the operator. On average brake tests applications last approximately 20-40 seconds. Plate brake testers and decelerometers use the vehicles inertia to provide the power to conduct the brake test, results have to be achieved in the time it takes for the vehicle to stop, brake testing results are typically taken in a couple of seconds.

Consistency

Roller brake testers are able to achieve consistent and repeatable results for brake tests for individual wheels to full brake effort or wheel lock up, while plate brake testers and decelerometers normally do not brake to full capacity, as this would be too dangerous. The brakes are tested to try to exceed a pre-defined deceleration and if this figure is exceeded then the brakes are deemed to be ‘good enough’.

Installation

The roller brake testers are compact but require sufficient room each side of the brake tester for the vehicle. Plate brake testers are the most space greedy, needing a large area for the plates and a suitable amount of room for acceleration and deceleration, including a safe overrun area. The decelerometer is the most space friendly, with no installation required for the vehicle mounted unit.

To give meaningful loading results with all three of the testers, the vehicle needs to be loaded to more than 60% of its carrying capacity, or in the case of the rolling brake tester, a simulated load applied.

To find out more about brake testers and how they can work with your vehicle workshop, get in touch with Levanta on 1300 577 541 or with your local office’s contact forms here.