How to choose the best option for your heavy vehicle workshop

In the realm of heavy vehicle workshops, the selection of the right foundation for maintenance pits holds paramount importance. Tradition has favoured concrete pits for decades, given their reliability and strength. However, a modern contender has emerged in the form of prefabricated steel pits to challenge the status quo. In this article, we’ll explore the merits of both options, making a compelling case for the advantages that prefabricated steel pits bring to heavy vehicle workshops in Australia and New Zealand, even in the face of financial considerations.

Ultimately, both concrete and steel workshop pits serve the same purpose, but the way they are constructed presents significant differences. Let’s explore into what sets them apart:

Concrete Workshop Pit:

- On-Site Construction: A concrete pit requires on-site form work, a process that consumes a considerable amount of time. The construction involves pouring the floor slab, forming or blocking up the side walls, and additional concrete and finishing work.

- Engineered Slab Overhang: Due to the pit’s width (around 1400mm) and the opening (950mm), an engineered concrete slab is necessary to overhang the pit edge.

- Integration Challenges: Integrating ventilation systems and jacking rails into the concrete pit can be challenging, often requiring additional effort and time.

Levanta Steel Prefabricated Workshop Pit:

- Ready for Installation: The Levanta Steel Prefabricated Workshop Pit comes pre-finished and ready for installation. It is lifted into position by a crane, backfilled, and the workshop slab is poured up to the edge of the pit.

- Engineered Design: The pit features engineered jacking rails and reinforcement on the side, providing peace of mind regarding durability and safety. Additionally, it comes with a 2pak epoxy coating inside and is wired to an isolator, requiring only one electrical connection to power up.

- Efficiency: The prefabricated pit minimises on-site construction time, as it arrives ready for use. The engineered solution ensures efficient integration of ventilation systems, jacking rails, and other essential components.

- HSE benefits: Safety benefits include the options to install forced ventilation, and an integrated and retractable safety pit cover, contributing to improved HSE measures.

- Enhanced work environment: In response to challenges attracting skilled mechanics, clients are focusing on creating better workspaces. A Levanta prefabricated pit offers a cleaner, brighter, and more ergonomically efficient and comfortable environment compared to traditional concrete pits.

The Cost Effective Choice

While the raw structure of a concrete pit might initially appear to be a cost-effective option, a closer examination reveals a different reality. The Levanta Prefabricated Workshop Pit proves to be a more economical choice when considering the following factors, many of which are necessary for compliance:

- Painting

- Ventilation, Including Entry Point Integration

- Explosion-Proof Lighting and Brackets

- Jacking Rails

- Alcoves inside Wall of Pit

- Stairs and Escape Ladders

- Compressed Air

All these components are seamlessly included in the Levanta Prefabricated Workshop Pit, eliminating the need for additional on-site labour and time-consuming tasks. By choosing prefabricated steel over concrete, businesses not only gain a more efficient solution but also avoid hidden costs associated with retrofitting and customization. In the long run, the Levanta Prefabricated Workshop Pit offers a superior, cost-effective, and time-efficient foundation for heavy vehicle workshops in Australia and New Zealand.

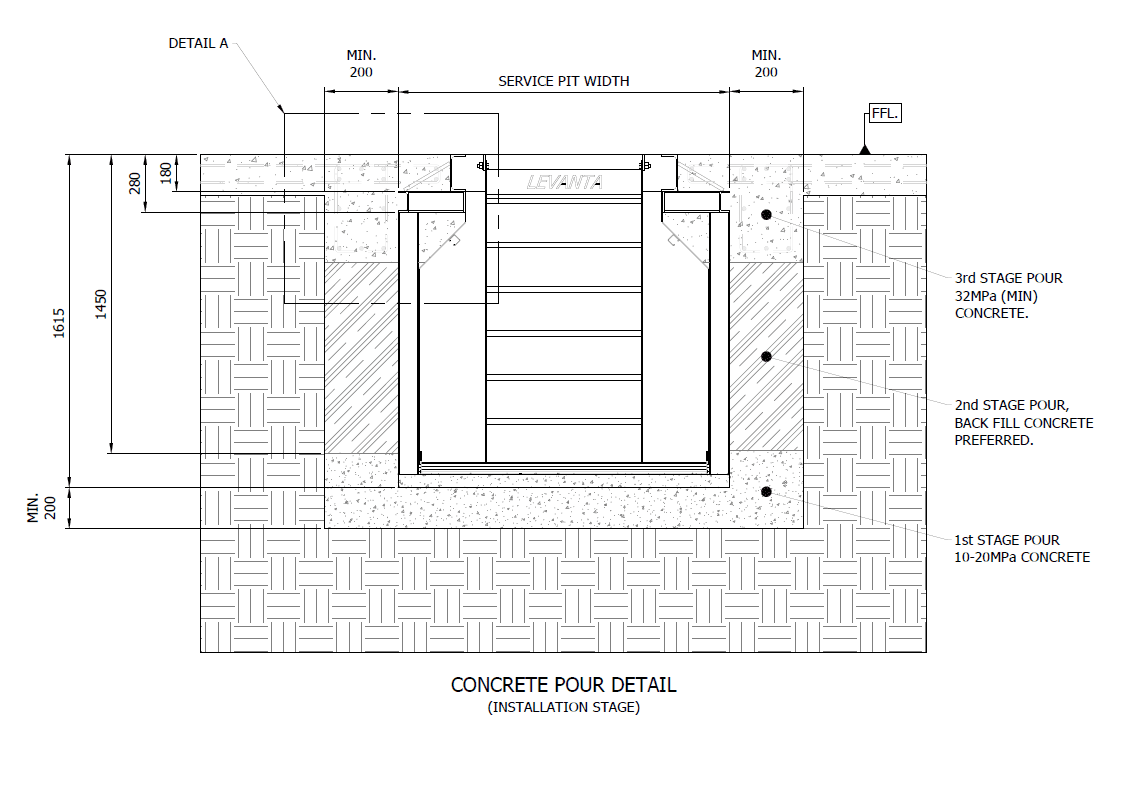

The following diagram is an end elevation of a Levanta Prefabricate Workshop Pit, it shows the construction detail as well as how the prefabricated unit is installed in the ground.

Call Levanta now on 1300 271 476 to find out how we can design, build, and install a durable prefabricated service pit for your heavy vehicle workshop.