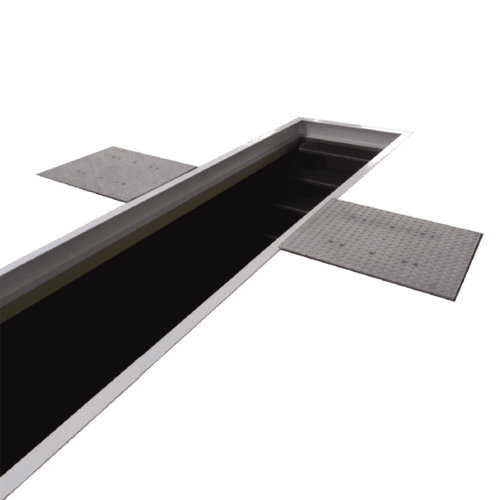

SB18115 Sherpa In-Ground Roller Brake Tester

About SB18115 Sherpa In-Ground Roller Brake Tester

Manufactured by Germany, this high-tech equipment benefits from 30 years of expertise and delivers state-of-the-art performance with uncompromising quality.

The SB18115 model is hot-dip galvanized for enhanced durability, making it resistant to corrosion and ideal for long-term use in demanding environments. As a standard feature, this roller brake tester comes equipped with a dedicated test program for electronic parking brakes, catering to the growing number of vehicles with advanced braking systems.

With its advanced technology and robust construction, the Sherpa Standard In-Ground Roller Brake Tester is the preferred tool for heavy vehicle workshops in New Zealand that strive to stay ahead in vehicle diagnostics and maintenance.

Technical Specifications

| Maximum Axle Load | 18,000Kg |

| Roller Length | 1,150mm |

| Roller Diameter | 268mm |

| Roller Centre Distance | 440mm |

| Test Speed | Planetary gear with 2.6 km/5.2km |

| Drive Capacity | 2 x 9 kW |

| Testable axle load | at 50% deceleration 16 t |

| Supply Voltage | 3PH 415V 50HZ |

| Feed line / fuse protection | 5 x 10 mm² / 50 A |

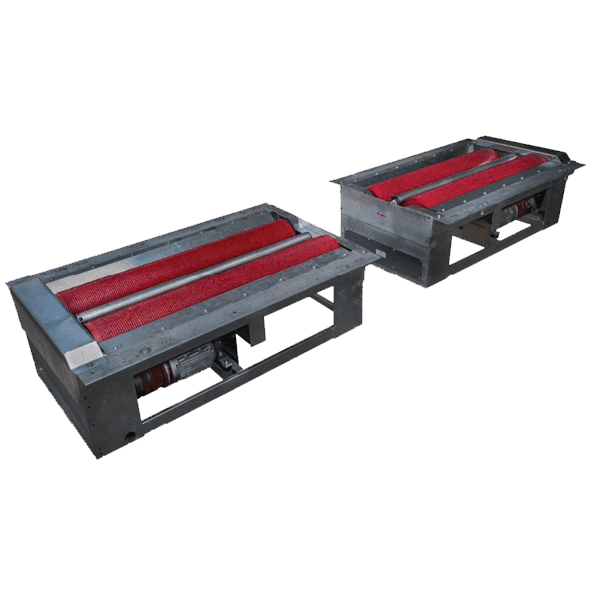

| Dimensions per roller set (L x W x H) | 1,220 x 1,045 x 545 mm |

| Weight per roller set | 460Kg |

| Wheel deflector | inner |

Product Features

Roller Brake Tester

- Hot-dip galvanised roller set

- Planetary gear motors: Enormous motor power with minimal power connection values

- Standard raised roller by 40 mm on the access side, exit side at ground level

- Wear-free, electronic DMS measuring system with shear force transducer

- Standard test program for electronic parking brakes

- EDOS Drive out assistance with electronic rotation direction controller (Patent EP 2594916)

Electrical / Control Box

- With motor protection switch, control electronics, operating elements and main switch lockable

- Splash water protected IP 54

- 800 x 600 x 250 mm (L x W x H)

Display Modes

LED Display “Dig-4” (RGB)

- With a resolution of 8×64 LEDs for all roller brake testers & test lanes, as a single or combined display

- Variable, dynamic display format

- Digital display with several display ranges for brake, difference, side slip, weight and pressure values

PC-Software “BPS-TV“

- The PC Software “BPS-TV” transmits data directly to the Windows 10 PC or Laptop

- Brake force, difference, axle number, brake type, axle and wheel weight, deceleration, brake pressures and operating mode are shown clearly and easy to read. The printout is processed via the PC

Additional Features

- SHERPA-Office database for customer and vehicle data: visual defects file, saving measurement

data, printout, network module for PC networking - Radio Remote controls: up to 20-times encodable; measured value storage and manual test unit control

- 2 test speeds (2.6 and 5.2 km/h) making it suitable for both heavy and light vehicle testing

- Weighing device static / dynamic: very precise and reliable measurement of the respective test weight by 8 shear force transducers

- Patented automatic all-wheel detection with fully automatic testing (Patent EP 1931957B1)

- EDOS Drive out assistance with electronic rotation direction controller (Patent EP 2594916)

Additional Load Simulation Options

In situations where a greater weight is needed, the SB18115 can be supplied with a Chassis Load Simulation system (SP10CLS).

Available Product Accessories

Hydraulically powered, these plates move laterally and lengthwise to detect worn-out or loose axle and steering components with pinpoint accuracy.

The SP10CLS axle load simulation system is ideal for heavy vehicle workshops and testing facilities, offering unmatched precision for vehicle safety assessments.

Enquire about this product

Enquire about this product

Servicing

Hoists and other equipment in your workshop need annual servicing and certification by law for you to continue working safely and productively in your business. With our 34-point checklist and manufacturer trained servicing agents, you can be assured that your workshop equipment will work when you need it do, with the minimum downtime!

We deliver Australia-wide

Levanta’s national network of warehouses enables us to supply our workshop equipment direct to you, wherever your business is located right throughout Australia. Whether you need a service pit for a remote Pilbara mine or a 4 post hoist for a Sydney dealership workshop, we have delivery options to suit you.

Warranty

All Levanta products are backed up by an industry-leading warranty. We’ve invested our reputation into our quality brands, and we stand behind our products. Our dedicated team of design engineers work hard to detect and correct any issue – no matter how small – before it gets to our customers.