What you need to know about Non Destructive Tests for car lifts

As an employer you are responsible for showing a duty of care towards your employees. You want to sleep at night knowing that you have done all you can to keep your staff safe.

One safeguard that’s widely recommended in the industry is to have your hoists undergo a Non Destructive Test (NDT) after 10 years of operation. An NDT is also recommended in the Australian Standards AS/NZS2550.9 and AS2550.1.

At Levanta we take safety very seriously. We believe that if you have followed the recommendation of the Australian Standards you are have safeguarded yourself and your business in the best possible way – while demonstrating you have done everything you can to comply to the standards.

Download our FREE guide to smarter workshop design

It’s not only an important safety consideration. Australian law stipulates that you must ensure compliance for your workshop by having an NDT for every hoist.

Automotive workshop safety for your staff, customers, and equipment

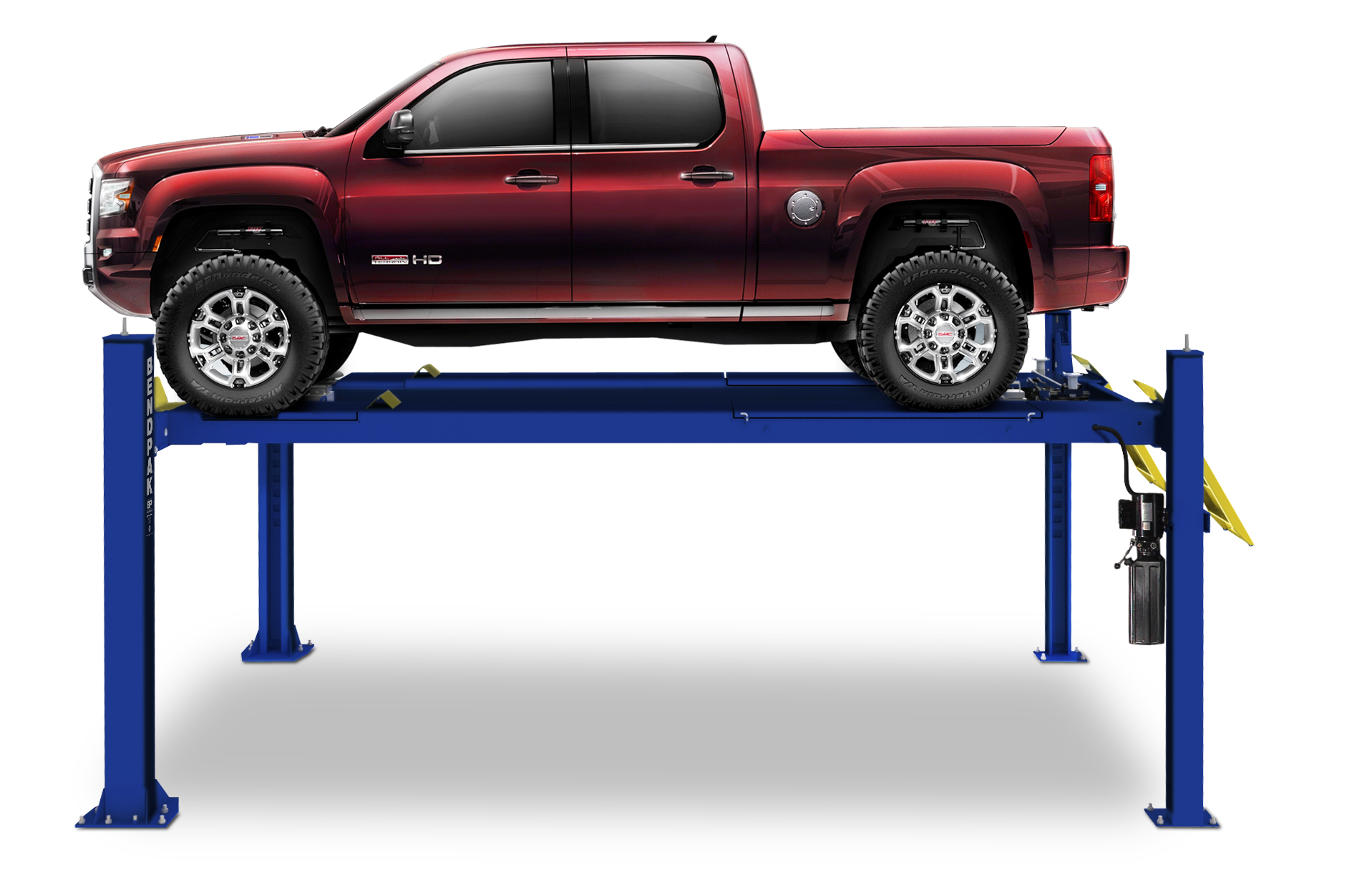

A Non Destructive Test is an x-ray of the structure of the hoist including all the welds to check structural integrity. With the weight of vehicles and the amount of work a hoist typically does each day, it’s important to check that your hoists have no chance of failure.

Non Destructive Testing isn’t just a matter of “do it once and then forget it”. After your hoists’ first 10 year NDT, you will need to have an NDT done every 5 years to ensure there is no further deterioration as time progresses.

So even once your hoists have first been tested (and you’ve paid for any faults to be rectified), you’ll still need to make allowance for subsequent future expenses.

And it’s not just the price of testing to factor into your thinking. There’s business downtime and the cost of parts and labour to consider too.

Some car dealerships find it easier to write their hoists off over 5-8 years, which gives them an easy option to simply replace hoists as they approach the 10 year age mark.

An alternative to NDTs for your vehicle workshop

Instead of committing to the expense of a mandatory NDT – along with the indeterminate cost of rectifying whatever faults are found – it may be a better business choice to instead simply outfit your workshop with all-new hoist equipment.

With the latest gear, your workshop will enjoy many benefits over your former setup, such as increased efficiency, greater appeal to qualified staff, and better ability to meet your OEM’s Corporate Identity requirements.

To help you decide whether an NDT or new hoists is the best option for your business, we’ve put together a free checklist that runs through the pros and cons of each alternative.

It’s not a sales pitch. It’s designed to be an accurate summary of your options as a workshop business owner or manager, to help you make the right decision for your situation.

Find the best way to ensure your workshop is compliant

To find out more about whether an NDT or a new fitout of workshop hoists is the best option for your business, get in touch with Levanta today. Our garage equipment experts will explain your options and help you decide on the best way forward for your workshop business.

Call Levanta now on 1300 577 541 or contact your local branch here to find out more about the latest technology vehicle hoists for your vehicle workshop.